|

Blue INNOship has led to the development of CO2 reducing technologies at app. 40% of the participants in Blue INNOship. Blue INNOship fact #2 |

Finalized

Project #14

Encapsulated biocides

| Goals and objectives |

|

This project aims at controlling the leach rate of biocides. Controlled release will lead to more effective use of biocides, thereby increasing the longevity of the coating and decreasing the environmental impact. A longer lasting hull coating will lead to economic benefits for the ship owners and allow coating manufacturers to obtain premium price for their product. The more effective use of biocides will reduce the environmental impact of hull coatings.

|

| Participants |

|

HEMPEL

Danish Technogical Institute

|

| Outcome from the project |

|

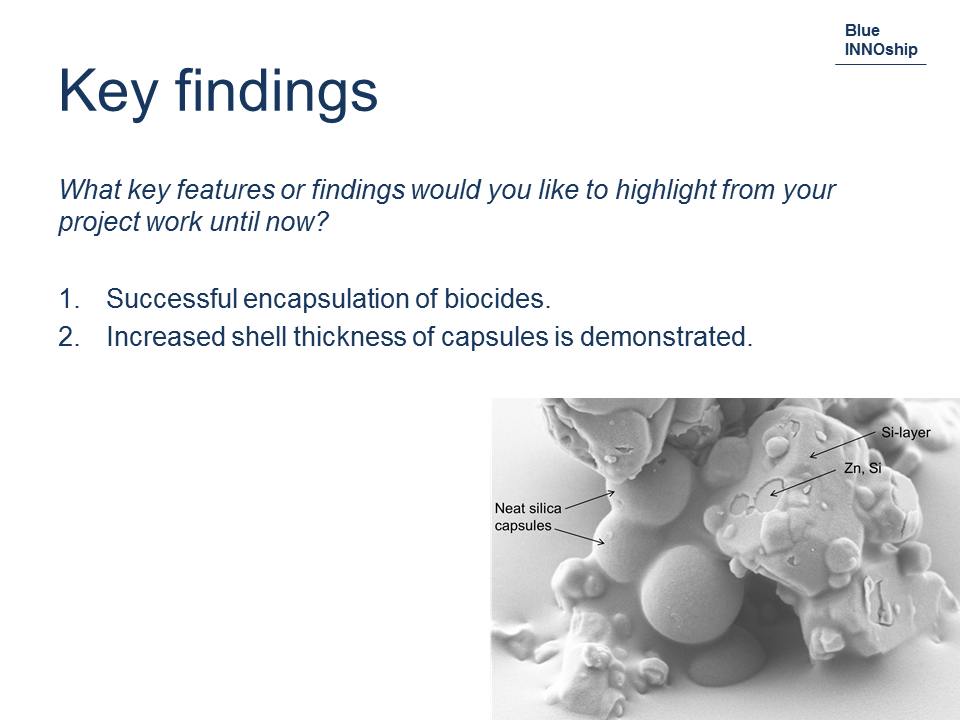

- Development and tests of three encapsulation techniques.

- Raft tests on various metal pyrithiones.

|

| Reporting from the project |

|

How would you describe the results obtained in the project?

We have tested three different encapsulation approaches in the project in order to obtain the desired release of the biocides. None of the approaches gives rise to the desired release. Hence, the results cannot be directly implemented in a product at Hempel. However, it is of high value for Hempel now to be able to conclude that encapsulation should not be used in their hull coatings in order to get reduced release of biocides. Hempel has spent many resources in the past to investigate encapsulation, and Hempel now has the scientific basis to conclude that they should discontinue investments in encapsulation. Instead, as a direct consequence of the BlueINNOship project, Hempel and Danish Technological Institute (together with DHI) have initiated a new project on development of new catalysts.

Further, during the BlueINNOship project, we discovered that another solution that is possibly a good biocide. This is currently undergoing further investigations at Hempel.

How would you describe the process leading to these results?

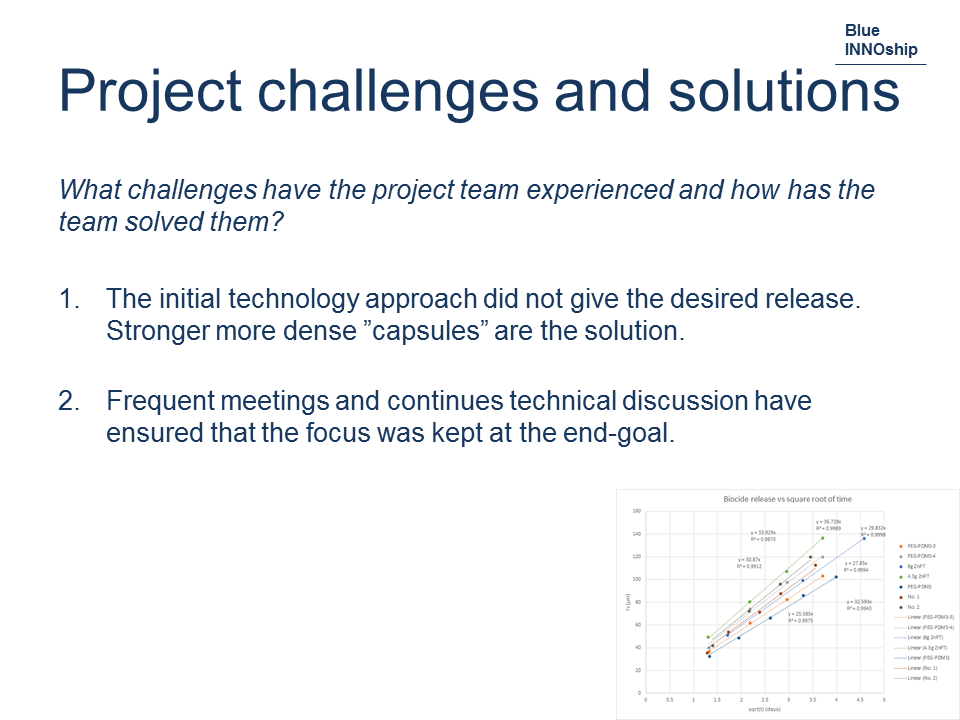

The process has been pragmatic and goal oriented. At each project meeting, the current strategy was debated and, if needed revised. Hence, the resources in the project were optimized and we have managed to investigate three different encapsulation technologies and not only one.

Please summarize the key activities conducted in the project

Three different technologies for encapsulation have been evaluated through an assessment program, i.e.

a) encapsulation of a biocide, b) characterization of the synthesized particles, c) integration of the encapsulated biocide in a hull coating, d) release of the biocide in the hull coating, e) raft tests of hull coatings performed in relevant environment. Were there any concerns about the projects outcome during the project and how did you overcome them?

Yes, the results were continuously evaluated because we were concerned that the applied strategies would not be able to fulfill the required demands. Based on these discussions, we decided to change strategy twice.

Which positive findings or news did your project disclose?

The most valuable finding is that Hempel can close the idea about encapsulation on a scientific basis.

We found an interesting candidate as a new biocide. Hempel is now investigating this in further detail.

Why was the project worth the invested resources?

The most valuable finding is that Hempel should not continue to invest resources in encapsulation as a method to obtain reduced release of biocides in silicone coatings. By closing the encapsulation idea, more resources can be used for other R&D ideas.

The project has contributed to the discovery of the value in minimal viable product (MVP). A MVP mindset is now being implemented at Hempel.

The project has initiated a new strong relationship between Danish Technogical Institute and Hempel. Danish Technogical Institute and Hempel has now started a new project on the development of a new catalyst to Hempel’s silicone coating.

Both Danish Technogical Institute and Hempel have obtained valuable technical knowledge and experience about joint R&D project.

What key learnings did you obtain through the project?

Close collaboration is very important for an optimal outcome and an optimal use of resources.

A constant debate about the project strategy in relation to the project aim ensures the projects value.

How was the cooperation between the partners?

The collaboration was very good and became better during the project period. It took some time to get to know each other and to optimize the collaboration. More frequent phone meetings as well as physical meetings were important. Further, one of Hempel’s specialists visited Danish Technogical Institute one day in the lab, which further improved the mutual understanding.

Danish Technogical Institute has had two replacements of personnel during the project, due to maternity leave and job change. Both Danish Technogical Institute and HMP agree that it has not caused any significant problems for the project, mainly because of a good knowledge transfer at Danish Technogical Institute and because there was a sufficient overlap between the replacements.

What could have made the cooperation work better?

More frequent meetings earlier in the project period. It takes time to get to know each other; get to know each other’s competences and way of work; as well as a mutual understanding of the project goal. Hence, it is important to meet frequently, especially in the beginning of the project.

Did any partners not deliver as anticipated? And what did you do about it?

Both partners delivered as promised.

What could have made the project work better?

With more frequent meetings in the beginning of the project period the use of resources could have been optimized. This could potentially have led to more work and understanding on the later encapsulation approaches.

Did you have to change scope or process during the process in order to finalize the project?

We did not change scope, but we changed the encapsulation technique twice.

Blue INNOship has allowed pragmatic project management. This has prompted that Hempel has gotten courage to participate in similar R&D projects outside of the company.

It makes sense to have a few short status reports that force the project partners to evaluate the progress. Further, it keeps the Head of Blue INNOship, Magnus Gary, updated with the overall status of the project.

Many funded R&D projects (e.g. under EU) require that the developed technologies end in a product. In our project, this has not been the case, but the project has still created value. We acknowledge Blue INNOship for making this possible. Further, we have had the possibility to change approach twice, which allows for optimum use of resources when initial ideas are re-evaluated.

|

| Presentations, articles and media coverage from the project |

|

Presentation of finalized Encapsulated Biocides project, November 2017

Poster titled “Biobased polymers employed in biocide encapsulation” was presented at 6th international Conference on Biobased and Biodegradable Polymers, Mons, Belgium, 11-13 September 2017.

|